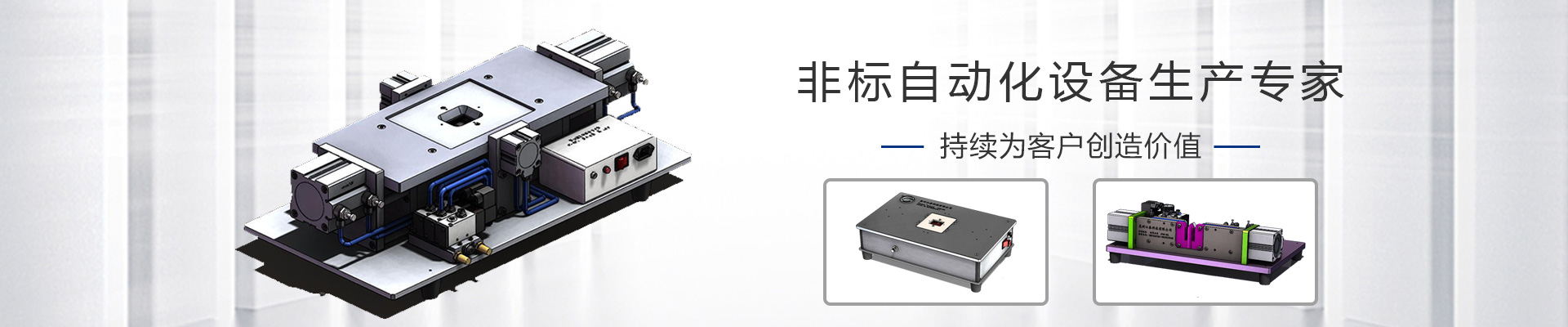

Product Name: Pulling and Cutting Forming Integrated Machine

Model: JT60-35

Equipment performance and characteristics:

The characteristics of our company's models are reflected in the ability to complete stretching, shearing, and shaping work, with the entire process completed within 1-4 seconds. A circular inductor pin cutting and shaping equipment with high processing efficiency, good product quality, and reduced labor costs, with different speeds for different models. Due to its stable equipment and wide adaptability, it is loved by the circular inductor processing industry.

JT60-35

Magnetic ring type: outer diameter 9-45mm;

Maximum foot pitch: 30mm;

Maximum row spacing: 25mm;

Wire diameter range: 0.8MM-1.6mm;

Average output value: 1000-2000PCS/hour

Working principle: clamping pulling shaping cutting;

Best use: Used for pre cutting semi-finished products and cutting the feet of a single finished product without the bottom plate. The principle of the machine is that after stretching and shaping, the product will not rebound, and the consistency of the cut product's foot position is good.

Capacity calculation:

Considering that employee proficiency requires a process, calculate based on average output/PCS

Part number single completion time/s average production capacity/H average production capacity/8H 10 day production capacity/8H

3 900 7200 12000

4 800 6400 9000

2 1300 10400 15000